If you are looking for a machine to treat sewage with a large amount of suspended matter or sewage with high oil content, such as to treat micro-polymers such as algae in water, then the dissolved air flotation system produced by BETTER EPT is your best choice. The scum produced after treatment can be automatically discharged, and the solid matter in the discharged scum is up to 30-100g/L.

| Model | Treating Capacity(m3/h) | Dissolved Air Water(m3/h) | Main Motor power(kW) | Scraper power(kW) | Air Compressor power(kW) | Dissolved Air Tank Size(mm) | Overall Dimension(mm) |

| YW-05 | 4-5 | 1.5-2 | 3 | 0.37 | 1.5 | Φ400×1000 | 3300×1800×2200 |

| YW-10 | 8-10 | 2-3 | 3 | 0.37 | 1.5 | Φ500×1512 | 4000×2100×2200 |

| YW-15 | 10-15 | 4-6 | 3 | 0.37 | 1.5 | Φ500×1512 | 4400×2100×2200 |

| YW-20 | 15-20 | 5-7 | 7.5 | 0.37 | 1.5 | Φ500×1512 | 4600×2400×2200 |

| YW-30 | 20-30 | 6-10 | 7.5 | 0.37 | 1.5 | Φ500×1512 | 5200×2600×2400 |

| YW-40 | 30-40 | 8-13 | 7.5 | 0.55 | 1.5 | Φ600×1880 | 6000×2600×2400 |

| YW-50 | 40-50 | 15-20 | 7.5 | 0.55 | 1.5 | Φ600×1880 | 7000×2600×2400 |

| YW-60 | 50-60 | 18-27 | 7.5 | 0.55 | 1.5 | Φ600×1880 | 7600×2800×2400 |

| YW-70 | 60-70 | 22-30 | 7.5 | 0.55 | 1.5 | Φ650×2034 | 8400×2800×2400 |

| YW-80 | 70-80 | 24-32 | 7.5 | 0.55 | 1.5 | Φ650×2034 | 9200×2800×2400 |

| YW-100 | 90-100 | 30-35 | 15 | 0.55 | 3 | Φ700×1980 | 10000×2800×2600 |

| YW-150 | 125-150 | 60-80 | 22 | 1.1 | 3 | Φ800×1980 | 13500×2800×2600 |

| YW-200 | 175-200 | 80-100 | 22 | 1.1 | 3 | Φ800×2100 | 15800×2800×2600 |

| YW-250 | 225-250 | 110-120 | 22 | 1.1 | 3 | Φ800×2400 | 18000×2800×2600 |

| YW-300 | 280-300 | 120-180 | 37 | 1.1 | 5.5 | Φ1000×2900 | 19200×3400×2800 |

Industries served include glass manufacturing, paper mills, food and dairy processing, meat, fish, and poultry slaughterhouses, and waste vegetable oil recycling.

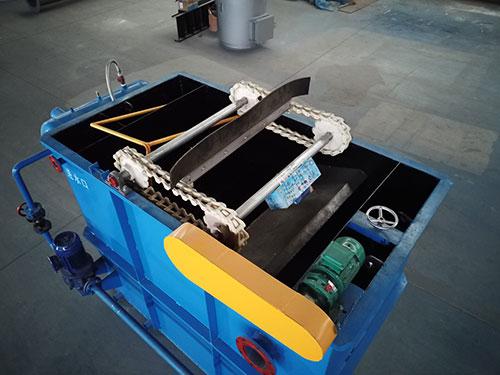

The chain and sprocket wheel of the scraper device

The chain and sprocket wheel of the sludge scraper of the dissolved air flotation system produced by BETTER EPT are made of nylon material, which gives the chain and sprocket wheel good mechanical strength, wear resistance and shock absorption. It can also effectively separate the solid and the liquid in the scrum area.

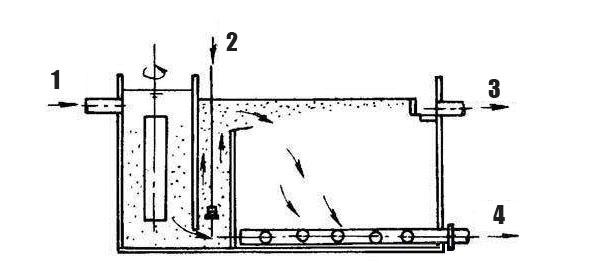

Releaser

The releaser is one of the most important components of the dissolved air flotation system, the function of which is to release bubbles in the sewage and with the bubbles adhering to the pollutants, the pollutants in the sewage will float to the surface under the reaction of buoyancy. The releaser produced by BETTER EPT is made of stainless steel material, so it’s more corrosion resistant. And with the countless micro bubbles released by the releaser, the removal rate of suspended matters is effectively improved.

Float Removal System

Float Removal System Reflux Pump

Reflux Pump Air Compressor

Air Compressor Dissolved Air Tank

Dissolved Air Tank

By releasing a large number of microbubbles in the sewage and with the bubbles adhering to the pollutants, the pollutants in the sewage will float to the surface under the reaction of buoyancy. And after the sludge is discharged by float removal system, the solid and the liquid are effectively separated.

We are a trusted manufacturer of wastewater treatment equipment and have been constructing complete wastewater treatment plants with over 18 years of experience. We have provided complete sewage and wastewater treatment solutions for industrial and municipal applications. We can configure the plant with the right machines to meet customer requirements. Whether you need sewage and wastewater machines or plants, we have the capability to provide custom products for you.