We are a direct factory with over 18 years of experience in manufacturing waste treatment plants.

Our factory is located at No. 1501, Zhucheng City, Shandong Province, China, about a 2-hour drive from Qingdao Airport. We’d be happy to pick you up—visitors are always welcome!

No, there’s no minimum order quantity, although we offer discounts for larger orders.

Yes, we are ISO and SGS certified.

Absolutely. Our professional design team can create custom drawings based on your specific needs.

Simply provide us with details on your water sources, water quality, flow rate, and available ground area. Contact us for further assistance.

We accept T/T and L/C. A 30% deposit is required by T/T before production, with the remaining 70% payable by T/T before shipment.

Delivery depends on the order size and item, but generally, it’s within 4 to 6 weeks.

We use standard packaging. Special packaging is available upon request, with any additional costs covered by the customer.

We use globally recognized paints like Sigma Coatings and PainBow, following a strict painting process for optimal protection.

Our advanced machining includes laser/plasma cutting, automatic welding, and CNC cutting and bending.

We provide detailed installation drawings. If needed, technicians can assist on-site, with travel and accommodation costs covered by the buyer.

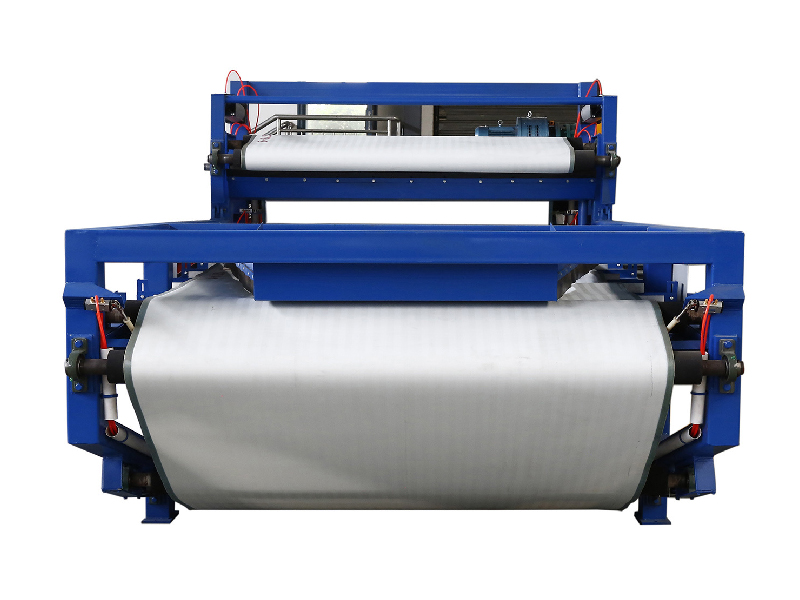

The belt filter press is a type of material dehydrating equipment, which can be used with air flotation equipment to dehydrate and press the suspended matter and sludge produced after air flotation process into filter cake to prevent pollution.

The plate and frame filter press is a kind of solid-liquid separator with a wide range of application and is easy to operate. The filter chamber is composed of a filter plate and filter frame.

The horizontal decanter centrifuge is mainly used to separate solids and liquids in different sewage, such as, residential wastewater, industrial wastewater, chemical wastewater, and wastewater in food, pharmacy, mining, petrochemical and many other industries.