In the Philippines, a dissolved air flotation machine was loaded for a 100 cubic meter (cbm) slaughterhouse wastewater treatment project.

A rural domestic wastewater treatment project with a capacity of 5 to 30 tons per day (TPD) was implemented.

A 300 tons per day (TPD) slaughtering wastewater treatment project was implemented in Egypt.

A 150 tons per day (TPD) domestic wastewater treatment project was carried out.

A client from Philippines purchased our incinerator to treat dead chicken waste. This greatly prevented the growth of bacteria and the spread of disease, harmless disposal.

African Hospital purchased our waste incinerator to treat 500kg medical waste per hour.

A client, a food company in Shandong purchased our equipment to treat 2000 tons of slaughterhouse wastewater per day.

A client from Ghana purchased equipment that can treat 120 tons of residential sewage per day.

A hospital in India purchased a wastewater treatment project that can treat 150 cubic meters of hospital sewage per day.

A client from Saudi Arabia purchased our equipment to treat 300 tons of slaughterhouse wastewater per day.

A company in Bangladesh purchased five economical, mobile incinerator system to destroy medical waste in rural clinics and hospitals.

Angola power plant purchased equipment that can treat 5 cubic meters residential sewage per hour.

A client from Kuwait purchased 12 small-sized residential sewage treatment plants for treating 10 tons of daily residential sewage.

A client from Argentina purchased two package sewage treatment plants and a media filter to treat 300 tons of residential sewage every day.

An Argentine customer implemented a 300 tons per day (TPD) factory wastewater treatment project for their new industrial plant, covering 25,000 square meters.

Residential wastewater comes from the daily activities of people, mainly from residential buildings and public buildings, such as residences, offices, schools, hospitals, shops, restrooms, etc. The pollutants contained in which are mostly organics including protein, carbohydrates and fat as well as numerous pathogenic microorganisms such as bacteria and viruses.

The mechanical bar screen produced by BETTER EPT can consistently and automatically intercept and remove all kinds of solid impurities from sewage.

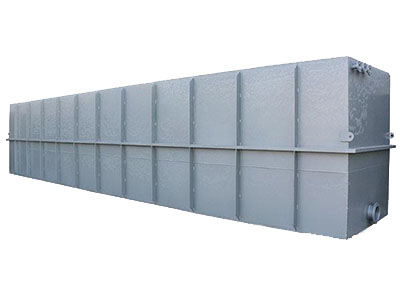

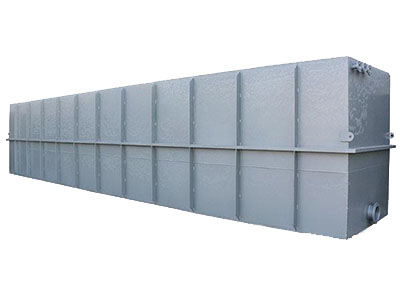

The package wastewater treatment plant produced by BETTER EPT can effectively remove BOD5, COD and NH3-N and can be built underground so it will not take up much space, or require constructing new buildings above the ground.

Apart from residential sewage, hospital sewage, especially that from contagious wards, also contains chemical substances, radioactive wastewater and pathogens, so it must be disinfected before draining. The sources and the components of the hospital sewage are sophisticated.

The package wastewater treatment plant produced by BETTER EPT can effectively remove BOD5, COD and NH3-N and can be built underground so it will not take up much space, or require constructing new buildings above the ground.

This chlorine dioxide generator uses sodium chlorate and hydrochloric acid (31%) as raw materials to produce a compound disinfectant that is mainly composed of chlorine dioxide and supplemented by chlorine gas which can be widely applied to disinfection treatment of drinking water, secondary water supply, swimming pool water and hospital sewage.

The pollutants in the slaughterhouse wastewater are mainly coming from blood, fat, animal hair, undigested food, feces, etc. The main pollutant in slaughterhouse wastewater is organics.

If you are looking for a machine to treat sewage with a large amount of suspended matter or sewage with high oil content, such as to treat micro-polymers such as algae in water, then the dissolved air flotation system produced by BETTER EPT is your best choice.

If you’re looking for a machine to remove suspended matter, grease and colloids from industry sewage and civil sewage, this cavitation air flotation machine is your best choice.

With grass stalks and wood pulp as raw materials, the procedure of pulping and papermaking includes pulping, washing, bleaching and papermaking. Alkaline pulping, semi-chemical pulping and mechanical pulping are current methods used for pulping in the paper mill industry.

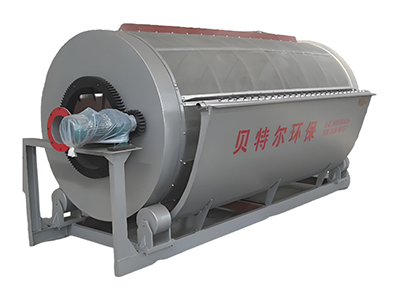

The rotary drum filter produced by BETTER EPT is widely used in a variety of solid-liquid separation occasions, such as residential sewage treatment, paper mill wastewater treatment, textile dyeing wastewater treatment, chemical sewage treatment, slaughterhouse wastewater treatment and so on.

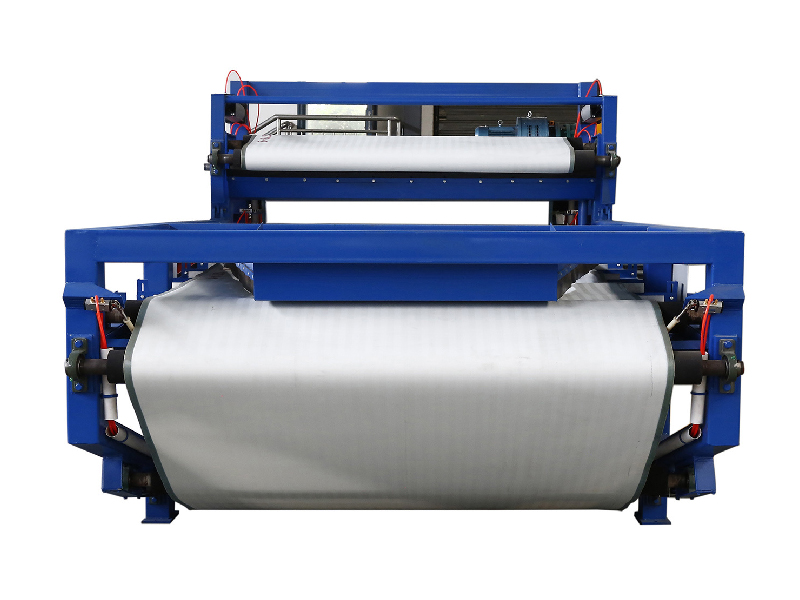

The belt filter press is a type of material dehydrating equipment, which can be used with air flotation equipment to dehydrate and press the suspended matter and sludge produced after air flotation process into filter cake to prevent pollution.

The quality and yield of electroplating wastewater is related to the processing conditions, production load, operation management, water use methods and other factors.

The inclined plate clarifier produced by BETTER EPT can improve the precipitation efficiency by fifty to sixty percent, and it’s widely used in industrial wastewater treatment, residential sewage treatment, non-ferrous metal processing wastewater treatment, power plant wastewater treatment, treatment of hydraulic dust removal wastewater, gas stations washing water treatment, biochemical water treatment and many other wastewater with various suspended matter purification.

The plate and frame filter press is a kind of solid-liquid separator with a wide range of application and is easy to operate. The filter chamber is composed of a filter plate and filter frame.

One of the features of the textile dyeing industry is using large quantities of water and releasing large amounts of pollutants. Processes such as dyeing are the main cause of pollution in the textile industry, in which a number of water, chemicals and dyes are used for producing textile products.

The volute dewatering press uses low-speed screw extrusion technology with lower electrical power consumption and it has function to concentrate the sludge, therefore, no concentration and storage unit is needed and the space of the whole sewage treatment plant and the costs can be reduced.

The mechanical bar screen produced by BETTER EPT can consistently and automatically intercept and remove all kinds of solid impurities from sewage.